QUALITY ASSURANCE IN ADDITIVE MANUFACTURING

Securing and verifying quality standards in 3D printing

Additive manufacturing is a trendsetting sector that already has one foot in series production. However, consistent quality assurance is still a challenge for many providers. With Quality Analysis you have an experienced partner for acclaimed quality assurance at your side from the start. We offer a suitable analysis method for every process step. Our experts are available to assist you and find a solution. Our service also includes highly precise results and evaluations in accordance with the standards.

POWDER AND MATERIAL CHARACTERISTICS

Analyse the quality of your powder and shorten your development process: with industrial computed tomography and high-resolution microscopy, we optimise process parameters and reduce the probability of defects at an early stage.

MATERIAL TESTING

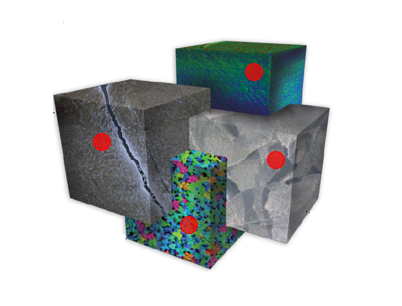

Your component has been printed. What does it look like inside? What characteristics does it have? With our material testing we can detect possible defects in the printing process at an early stage. Here we use non-destructive and destructive analyses and check the characteristics of the component and the material after printing using both industrial computed tomography and microscopic analyses.

DEFECT AND INTERNAL STRUCTURE TESTING

Erroneous process parameters can result in flaws in the material microstructure. We detect and localise such flaws for you, for instance delaminations, pores and failure mechanisms on the component. For this purpose we use non-destructive and destructive analyses.

DIMENSIONAL INSPECTION AND SURFACE TESTING

There are important prerequisites for the accurate assembly and correct function of your components: the surface must have the correct characteristics and all stipulated dimensions must be met. We analyse both these aspects using various analysis methods: depending on the measuring task, we use industrial computed tomography, tactile or optical metrology.

THAT COULD ALSO INTEREST YOU

Industrial Metrology

Discover the comprehensive possibilities of tactile and optical metrology for your quality assurance.

Industrial Computed Tomography

Learn more about the possibilities of non-destructive component analysis by means of CT.

Materialography

Discover the comprehensive analysis possibilities of destructive material testing.

QUALITY ANALYSIS,

YOUR PARTNER FOR YOUR ANALYSIS TASKS IN ADDITIVE MANUFACTURING

What can we analyse for you?

We would be pleased to advise you about the numerous possibilities and combined analysis methods.

The goal: the best, most cost-effective and most efficient analysis of your component.

Call us, we look forward to hearing from you!